Machining

From design to finished casting, our foundry brings every capability together.

Machining

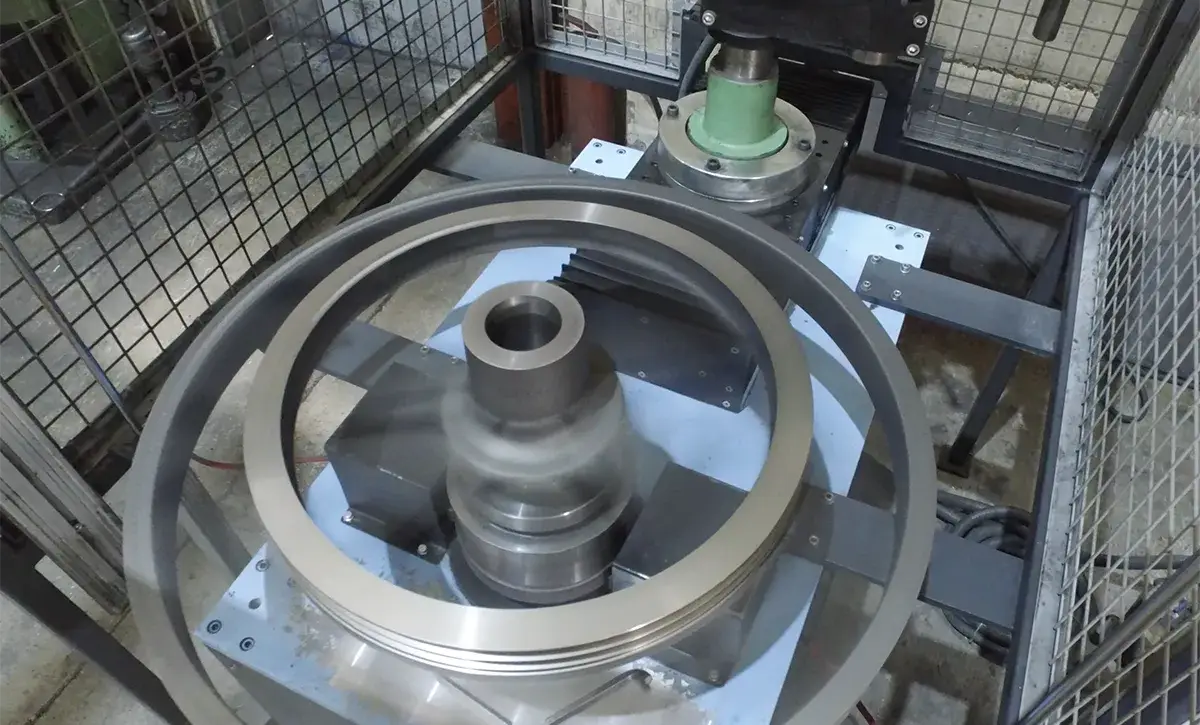

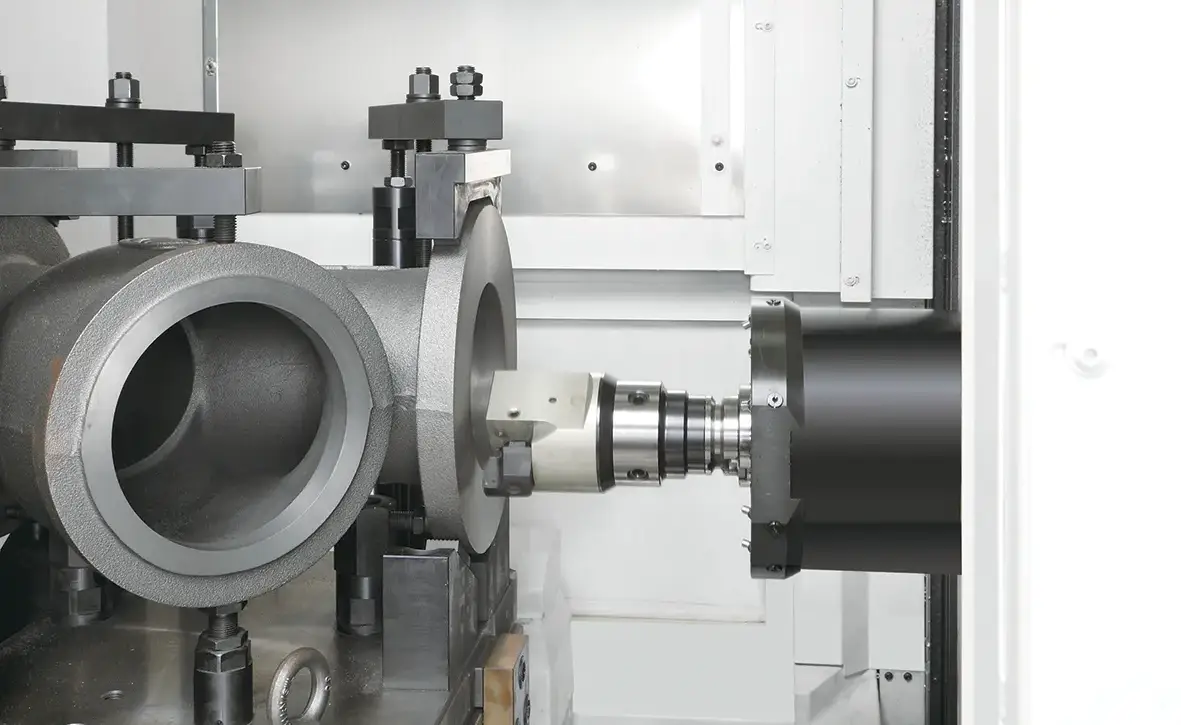

Atik Metal operates one of the largest and most advanced machining shops in Türkiye, equipped with over 120 CNC machines, including 10 five-axis units. Our fleet includes double-column machining centers, horizontal machining centers with pallet changers, CNC lathes, vertical turning lathes, and standard lathes. Many of these machines are robot-fed, enabling lights-out production, faster changeovers, and minimal downtime. This combination of automation, flexibility, and the latest CNC technology allows us to machine castings with exceptional precision and efficiency , covering everything from small, intricate parts to large, complex components.

We can machine parts up to 2,000 mm in height and 1,500 mm in diameter, giving us the ability to serve a wide range of industries, from precision engineering to heavy machinery. With over five decades of machining expertise, Atik Metal offers customers the unique advantage of sourcing both castings and fully machined parts from a single, integrated supplier.

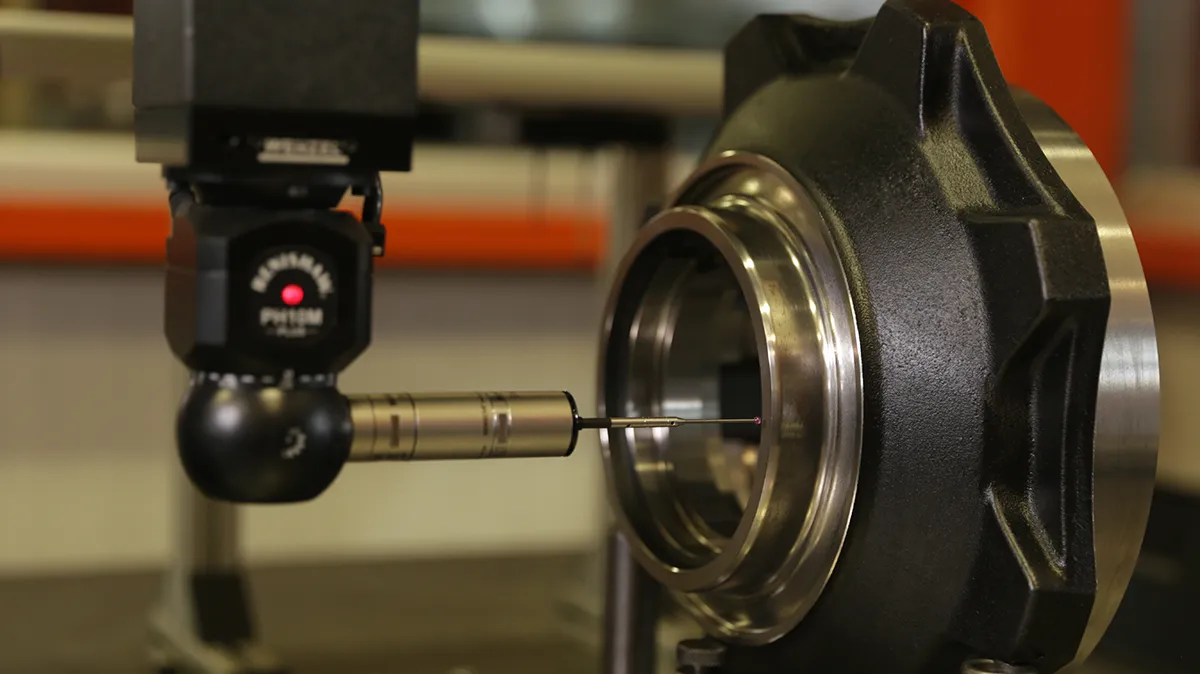

Partnering with global machine tool leaders such as Okuma, Mazak, and DN Solutions, we deliver components with tight tolerances, repeatable accuracy, and proven reliability. Our machining capacity, combined with lean manufacturing practices and advanced process control, ensures we meet the most demanding requirements of leading European OEMs, delivering ready-to-assemble parts at scale, on time, and with consistent quality.