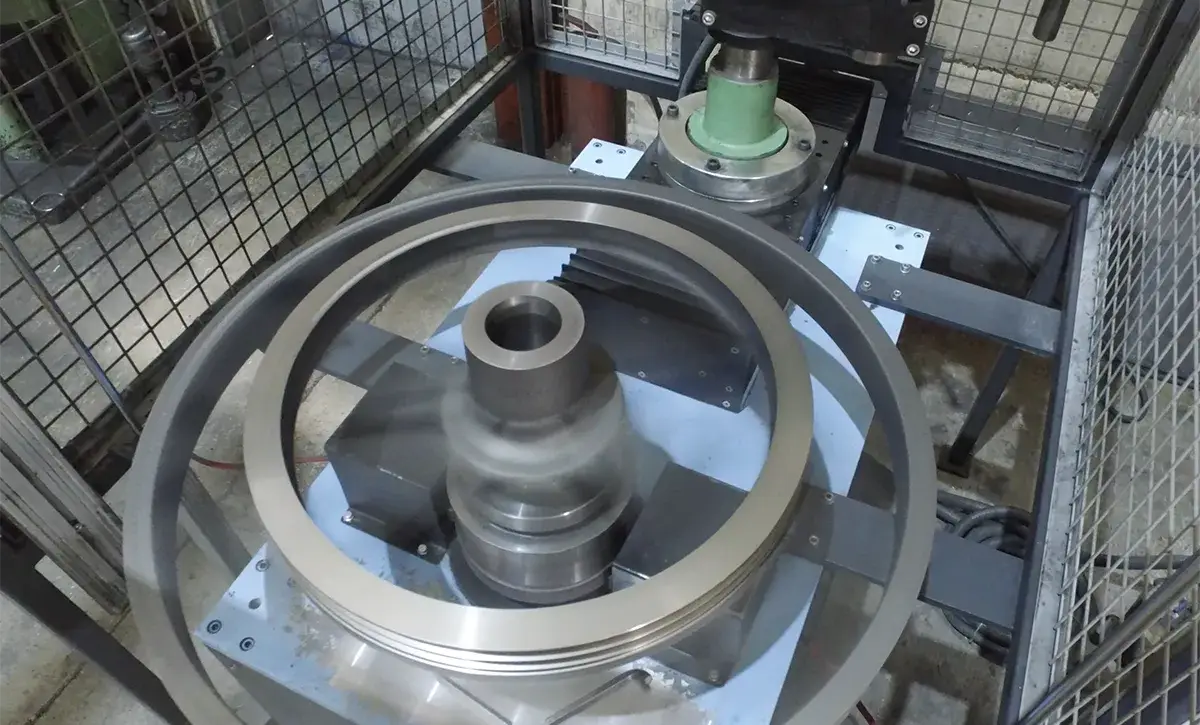

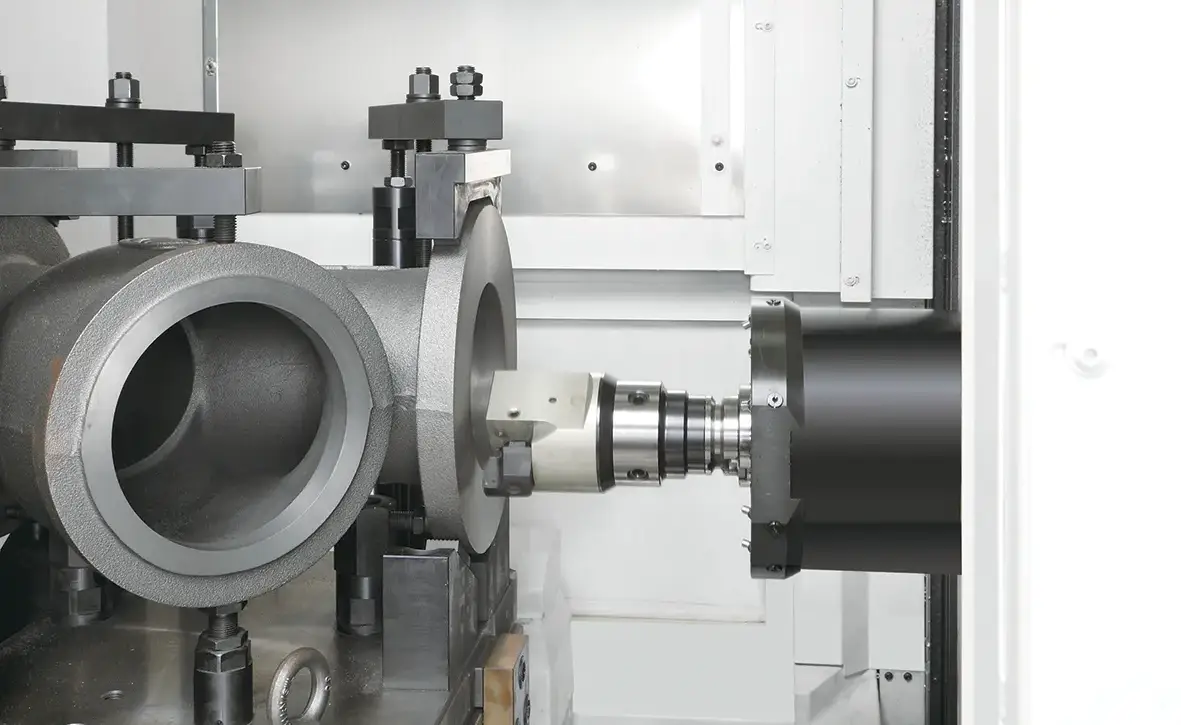

Machining

From design to finished casting, our foundry brings every capability together.

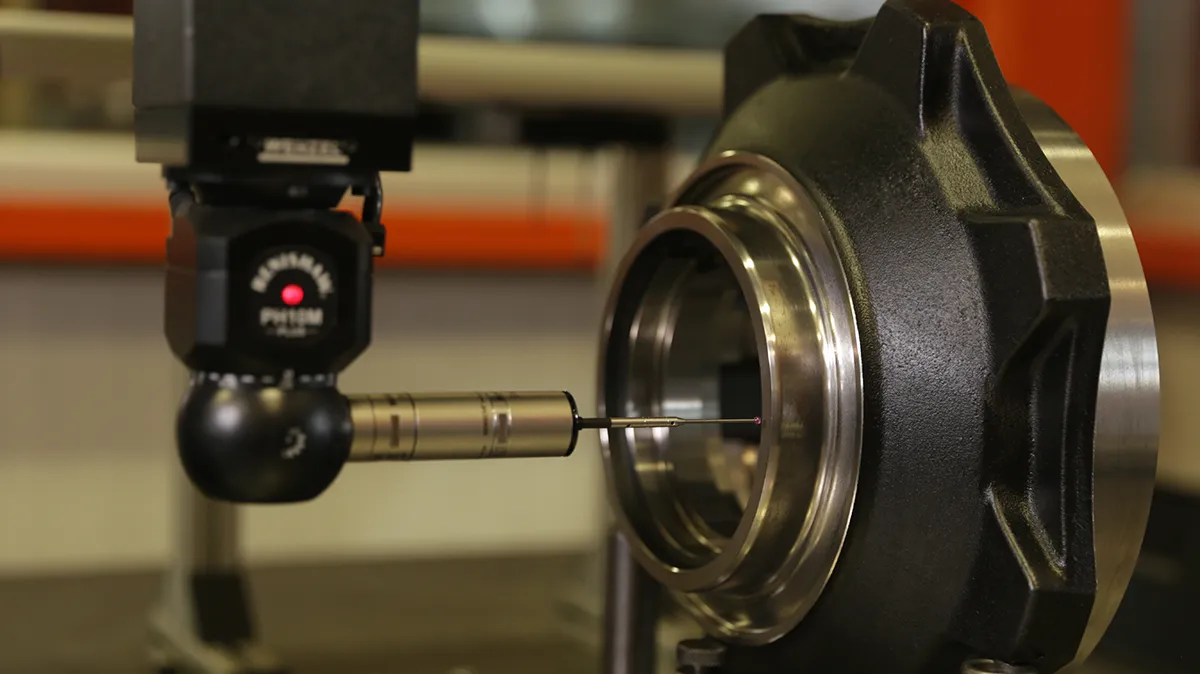

Dimensional Quality

Atik Metal’s Dimensional Control Laboratory plays a critical role in guaranteeing precision and reliability across every part we produce. Components are inspected continuously—both on the shop floor during production and within our dedicated Quality Department—to ensure compliance with customer specifications at every stage of the process.

Our laboratory is equipped with five CMMs (Coordinate Measuring Machines), supported by Tracer 2 scanners and a wide range of the latest dimensional measurement systems. This advanced equipment allows us to verify complex geometries, maintain tight tolerances, and deliver castings and machined parts that are fully validated for assembly.

Quality at Atik Metal goes beyond inspection. Through robust quality systems, operator training, and continuous improvement practices, we ensure that there are zero escapes—no nonconforming parts leave our facilities. Every measurement is logged, traceable, and backed by process documentation, reinforcing customer confidence and ensuring long-term repeatability.

By combining state-of-the-art measurement technology with a culture of lean manufacturing and continuous improvement, our Dimensional Control Laboratory helps us deliver faster, more cost-effective, and turnkey solutions without compromising quality, precision, or component performance.